¥2450.00

千业牌 定做非标连接尺寸 特殊轴电机 定制非标防爆变频电动机 质优价廉

新乡市恒通电机有限公司

河南 · 预售,付款后7天内

AEEVF3电机AEEV1H 品牌马达AEUVF3变频电机AEUV1H 特种电机AEEFF3 电动机AEVFF3; TEGH(AEHB)/TVGH AEEVJ3电机 AEEVJ2电动机 AEUVJ2 马达 AEUVJ3

seven、motor maintenance

1. The environment, in which the motor is operated, should be kept clean and dry, air inlet should not be hindered by dust or fibers.

only after the fault has been eliminated.

3. Should ensure that the motor is in running with good lubrication, according to the different operation conditions, every 500~1000 hours or so, the grease should be

added or replaced (for closed bearing the grease does not need to be replaced in the whole life). If the bearing is detected with overheating or lubricating grease

deterioration during operation, should change the grease in time. When changing grease, the old grease should be removed ar first, the oil bearing and bearing cover

of the oil tank need to be cleaned with kerosene, then grease 1/2 (level 2) or 2/3 (level 4,6,8) of the inner and outer cavity of the bearing.

4. At the end of the bearing life, the vibration and noise will increase when the motor is running, check the bearing radial clearance and replace the bearing.

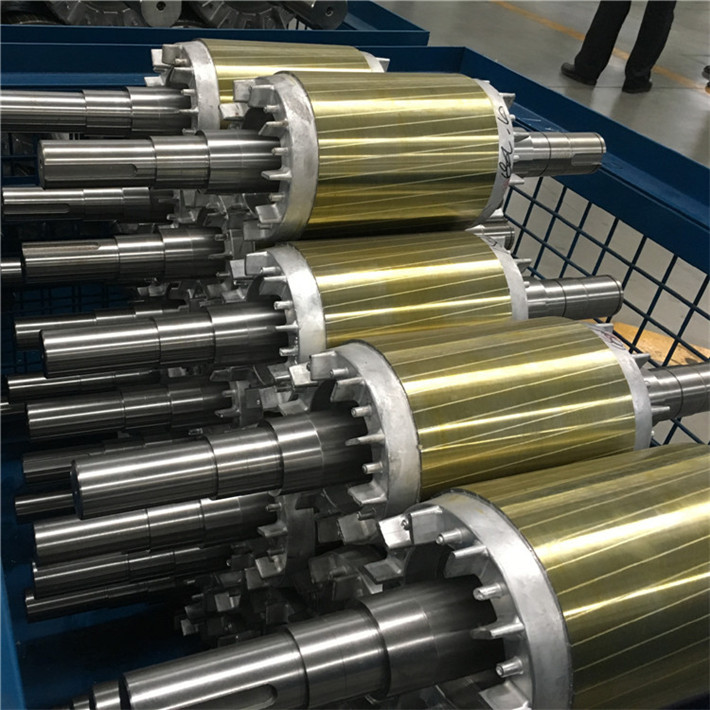

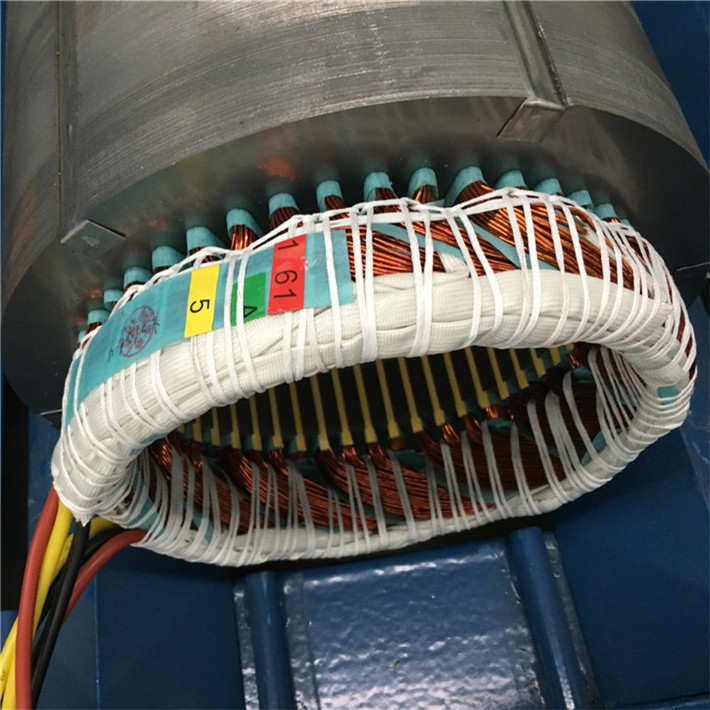

5. Remove the motor, the fan should be removed first, from the non shaft extension (the back end) out of the rotor. Attention, do not damage the stator

winding or insulation.

6. When the rotation direction of the motor does not meet the requirements, you can adjust the power phase sequence.

7. When the motor is holding for a long time after use, you should measure the insulation resistance.

- 起订:1

- 供应:3

- 发货:7天内